quotes and solutions

+8619870423316

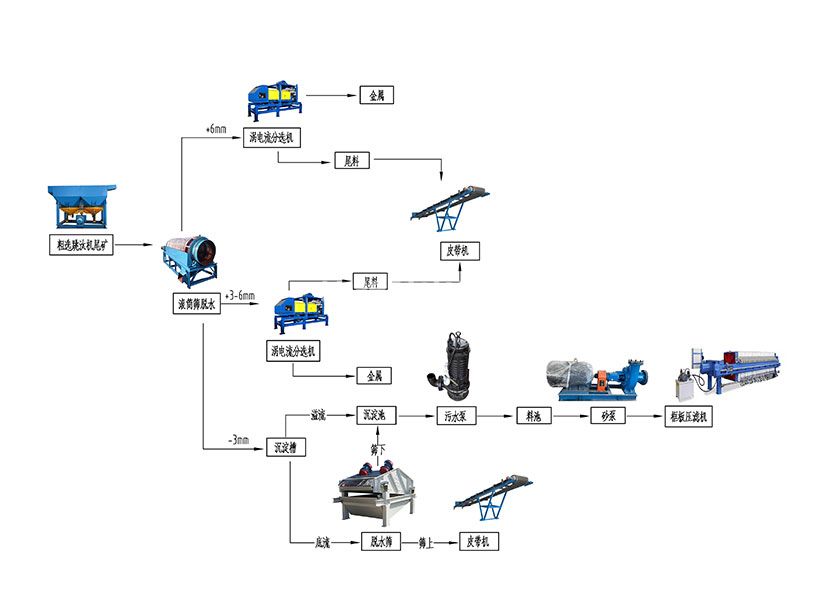

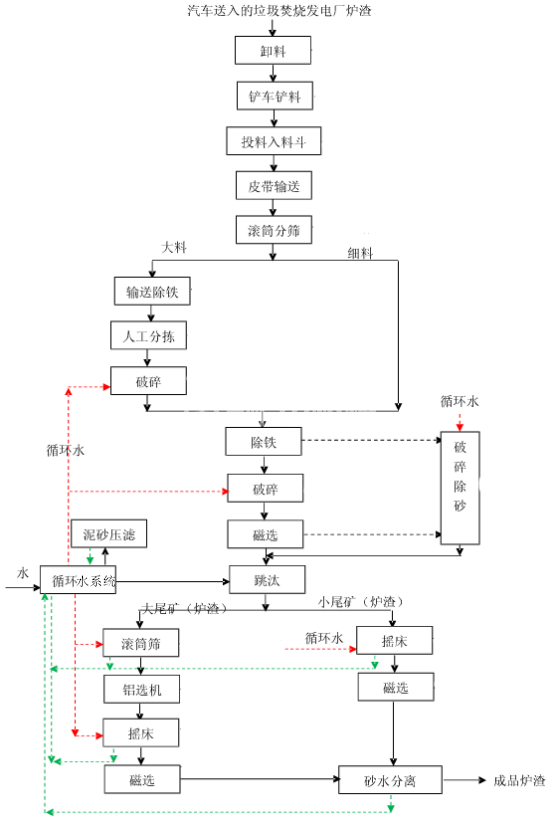

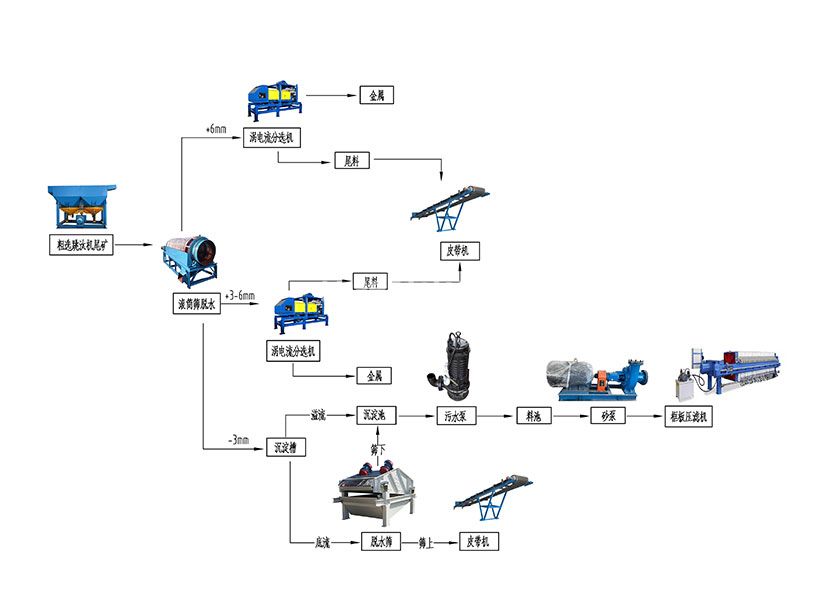

In power plants, slag is a common waste. If left untreated, slag can cause serious pollution to the environment. Therefore, power plants need to use slag treatment equipment to treat the slag. This article will introduce the relevant knowledge and operating steps of slag treatment equipment in power plants. What is slag treatment equipment? Slag treatment equipment is a type of equipment specifically used for treating slag in power plants. It can classify, separate, and treat slag, making it a reusable resource. There are many types of slag treatment equipment, including magnetic separators, vibrating screens, and grinding machines. Operation steps of slag treatment equipment 1 Pre treatment  Before slag treatment, it is necessary to pre treat the slag. Firstly, classify the slag into different types such as steel slag, slag, silicate slag, etc. Then, according to different types of slag, choose different treatment equipment for treatment. 2. Separating slag is the Committed step of slag treatment. Generally speaking, slag contains a large amount of metal elements such as iron, copper, aluminum, etc. Therefore, by using a magnetic separator to perform magnetic separation on the slag, the metal elements inside can be separated. At the same time, the vibrating screen can also screen the slag to separate impurities from it. 3. For some larger slag blocks, crushing is necessary. Pulverizer is a common slag crushing equipment that can crush slag into finer particles, facilitating subsequent treatment and utilization. 4. After the previous treatment, the slag has become a reusable resource. Steel slag can be used in fields such as road construction and cement production, slag can be used for soil improvement and cement production, and silicate slag can be used in fields such as glass manufacturing. Conclusion: The use of slag treatment equipment in power plants can turn slag into reusable resources and reduce environmental pollution. When using slag treatment equipment, steps such as pre-treatment, separation, crushing, and reuse are required. Through reasonable slag treatment, resource recycling can be achieved, contributing to environmental protection and sustainable development.

Before slag treatment, it is necessary to pre treat the slag. Firstly, classify the slag into different types such as steel slag, slag, silicate slag, etc. Then, according to different types of slag, choose different treatment equipment for treatment. 2. Separating slag is the Committed step of slag treatment. Generally speaking, slag contains a large amount of metal elements such as iron, copper, aluminum, etc. Therefore, by using a magnetic separator to perform magnetic separation on the slag, the metal elements inside can be separated. At the same time, the vibrating screen can also screen the slag to separate impurities from it. 3. For some larger slag blocks, crushing is necessary. Pulverizer is a common slag crushing equipment that can crush slag into finer particles, facilitating subsequent treatment and utilization. 4. After the previous treatment, the slag has become a reusable resource. Steel slag can be used in fields such as road construction and cement production, slag can be used for soil improvement and cement production, and silicate slag can be used in fields such as glass manufacturing. Conclusion: The use of slag treatment equipment in power plants can turn slag into reusable resources and reduce environmental pollution. When using slag treatment equipment, steps such as pre-treatment, separation, crushing, and reuse are required. Through reasonable slag treatment, resource recycling can be achieved, contributing to environmental protection and sustainable development.

Free design solution

Free design solution

24-hour engineer dispatch

24-hour engineer dispatch

In order to better serve you, we can leave your needs here, such as handling materials, production capacity, and finished product requirements. A professional product manager will reply to you!

Copyright: Jinqiang Mining Machinery

quotes and solutions

+8619870423316