quotes and solutions

+8619870423316

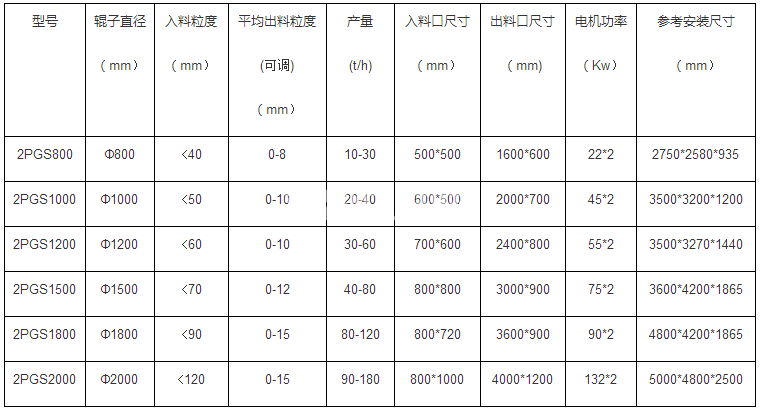

productivity:5-110t/h

Processing materials:Suitable for solid raw materials with tensile strength below 300Mpa and moisture content below 35%

Application scope:≤30mm

Feed particle size:≤30mm

Equipment processing capacity:5-110t/h

Production materials:Suitable for solid raw materials with tensile strength below 300Mpa and moisture content below 35%

1、 Overview

The double toothed roll crusher is a new type of toothed roll crusher developed and designed after doing a lot of market research work. For the key problems of sticking, blocking, particle size distribution failure, vibration, noise, smoke and dust, low efficiency, high energy consumption and high operation in the application of the fine crusher crusher, the new crusher after technical innovation is carried out. Solved the widespread problems existing in the fine crusher crusher, and completely solved the extreme office environment with high noise and smoke. Especially suitable for crushing coal gangue bricks, coal slime, pine wood particles, and peat. The key is applicable to thermal power plants. Because the coal used for heating furnace is generally clean coal that has not gone through grade classification, and the particle size distribution of clean coal does not conform to the provisions for coal used for heating furnace, crushing must be carried out. Therefore, the software of the coal handling system of thermal power plants should be equipped with slag extractors to crush the coal into a certain particle size distribution, so as to meet the provisions for ignition of the heating furnace.

2、 Application scope

The double toothed roll crusher is suitable for pelletizing, coal, concrete, aluminosilicate, Laminated glass, porcelain and other fields. It is suitable for crushing ductile raw materials with medium strength and below. It is mainly used for crushing iron ores. The double toothed roller crusher, also known as GF2PG double, belongs to the type of double roller crusher. The roller surface can be divided into large and small toothed rollers, which can be adjusted and manufactured according to the necessary specifications of raw materials. It is suitable for ductile and soft raw materials. The powerful double tooth roller crusher is suitable for the crushing of large and medium-sized coal mines or clean coal (including coal gangue) in fields such as coal, metallurgy, mining, chemical plants, decorative building materials, etc.

The double tooth roller crusher is suitable for the crushing rate and work of solid raw materials with tensile strength less than 300Mpa and moisture less than 35%. It can be widely used in fields such as mining, thermal power plants, concrete porcelain, metallurgical industry, chemical plants, decorative building materials, etc. It has the characteristics of low application and maintenance costs, reliable characteristics, low smoke and dust, and low noise.

3、 Working principle

The powerful double toothed roller crusher is composed of fast and super strong toothed rollers that run in opposite directions. The raw materials that meet the gap between the two toothed rollers fall down at random. The raw materials that exceed the gap between the two toothed rollers are crushed in a moment by the interaction of the teeth of the rollers, and fall down at random to achieve the purpose of crushing and reach the grain size distribution requirements. The operation of the relative roller differential can clear the raw materials between the teeth, thereby avoiding sticking and blocking conditions, and preventing the raw materials from being stuck on the toothed roller to prevent repeated crushing and not being excessively crushed.

4、 Equipment advantages

1. The double tooth roller crusher has a large crushing capacity. The motor and reducer are connected by a limited distance Fluid coupling to avoid driving force load. The inductor is protected against overpressure and reliable.

2. Adjusting the spacing between toothed rollers by hydraulic press, centralizing and moistening the rolling bearings of toothed rollers.

3. Tooth type reliability design, tensile Shear stress selection and crushing, low consumption, and uniform granulation.

4. The toothed roll crusher has the advantages of small size, large crushing ratio (5-8), low noise, simple structure, convenient maintenance, high production efficiency, uniform particle size distribution of crushed raw materials, low over crushing rate, convenient maintenance, smart overpressure protection, reliability and other characteristics.

Free design solution

Free design solution

24-hour engineer dispatch

24-hour engineer dispatch

In order to better serve you, we can leave your needs here, such as handling materials, production capacity, and finished product requirements. A professional product manager will reply to you!

Copyright: Jinqiang Mining Machinery

quotes and solutions

+8619870423316