quotes and solutions

+8619870423316

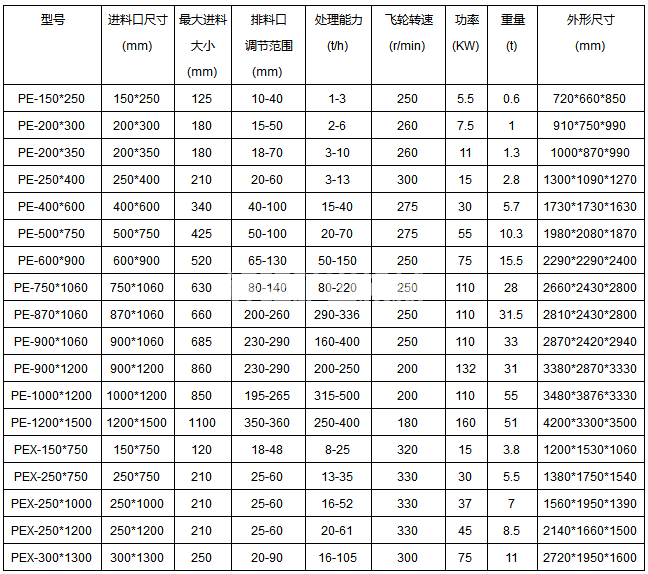

productivity:1-1000t/h

Processing materials:Dolomite, iron ore sand, slag, manganese ore, lead ore, ferrosilicon ore, artificial quartz stone, porcelain, and other solid raw materials with very high strength

Application scope:≤1200mm

Feed particle size:≤1200mm

Equipment processing capacity:1-1000t/h

Production materials:Dolomite, iron ore sand, slag, manganese ore, lead ore, ferrosilicon ore, artificial quartz stone, porcelain, and other solid raw materials with very high strength

1、 Application

The fine jaw crusher is suitable for crushing hard raw materials, such as dolomite, iron ore sand, slag, manganese ore, lead ore, ferrosilicon ore, artificial quartz stone, porcelain, and other solid raw materials with very high strength, with a secondary crushing rate. The Hubei type fine crusher is widely used in chemical plants, calcium carbide plants, thermal power plants for desulfurization, etc., and has remarkable crushing effect on dolomite and Calcium carbide.

2、 Structural composition

The key components of the E type fine crusher include a chemical frame, a camshaft, a large belt pulley, a water pump flywheel, a movable jaw, a side rain shield, an elbow plate, a rear seat of the elbow plate, a gap adjusting extruder screw, a calibrated torsion spring, a fixed fixed jaw plate, and a themed movable jaw plate. Among them, the elbow plate also has a commercial insurance effect.

3、 Basic Principles

The raw materials are fed into the feeding port of the crusher according to the feeding machine equipment (such as belt conveyor and plate feeder), and then enter the crushing chamber. When the raw materials encounter the high-speed running motor rotor pushed by the V-belt, they are severely hit by the drill bit head-on. The blocky raw materials were immediately destroyed, and the leftover materials quickly flew onto the counterattack board to carry out a second impact crushing. The rebound raw materials collided and crushed with the incoming raw materials afterwards; After being crushed in the first chamber, the raw materials are repeatedly crushed in the second chamber. Finally, they are filtered, rubbed, and crushed through a feeding grate to ensure that the specified raw materials are discharged from the grate gap. Coarse raw materials are returned to the first chamber for further crushing. Because there is a layer of floating raw materials gathered in the crushing chamber, the raw materials that enter the crusher afterwards are like shells shooting, and when they are shot into the gathered raw material layer, the crushing chamber is like;, The rapid collision between raw materials results in efficient material crushing, and the fine particles after crushing cause strong impact; And it causes many ultrafine powders.

4、 Advantage characteristics

1. High efficiency ultra-fine jaw crusher has large production capacity and fine commodity particle size distribution.

2. Selecting a three chamber inclined plane shaped crushing chamber increases the frequency of severe strikes on raw materials, hard extrusion molding, and reduces friction, thereby reducing drill bit wear. The high-efficiency ultrafine jaw crusher has a longer service life of wear-resistant materials;

3. The gap between the return plate and the drill can be adjusted conveniently, and the feed particle size distribution can be controlled reasonably;

4. Select a deflectable structure, which can prevent the drill bit from breaking to a certain level in case of hard raw materials;

5. Make maintenance more convenient, with hydraulic control valves for opening the meter cover equipment;

6. The gap between the left jaw plate, grate and drill bit is adjustable. When the particle size distribution exceeds the standard value, it can be adjusted in a different way;

7. Promote the selection of electric motors and immediately promote the organization to make the system software run more stably;

Free design solution

Free design solution

24-hour engineer dispatch

24-hour engineer dispatch

In order to better serve you, we can leave your needs here, such as handling materials, production capacity, and finished product requirements. A professional product manager will reply to you!

Copyright: Jinqiang Mining Machinery

quotes and solutions

+8619870423316