quotes and solutions

+8619870423316

Optional process:Gravity separation, flotation, chemical separation (mixed mercury method and cyanide method)

Process output:Customizable, develop configuration plans based on customer needs

Equipment Composition:Shaker, jig, centrifugal gold separator, linear vibrating screen, circular vibrating screen, ball mill, flotation machine, gold mill, crusher, classifier and other related equipment.

Shaker, jig, centrifugal gold separator, linear vibrating screen, circular vibrating screen, ball mill, flotation machine, gold mill, crusher, classifier and other related equipment.

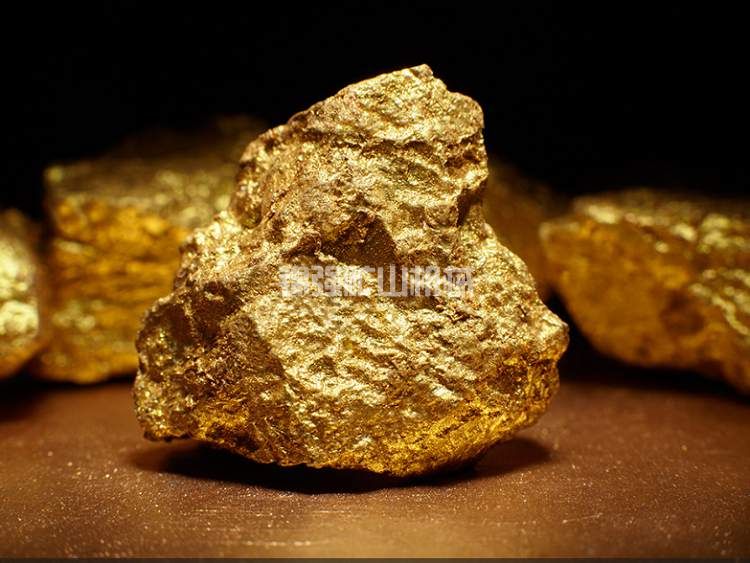

1、 Overview

The gold ore beneficiation process is also known as the gold ore beneficiation process, and in some places it is directly referred to as the gold ore beneficiation method. Jinqiang gold mine has advanced beneficiation methods and sophisticated equipment. At present, China has discovered 98 types of gold deposits and gold bearing minerals, of which only 47 are common, and only 10 or more minerals are directly utilized in industry. There are nearly 38 gold bearing substances in China, and the gold content in gold mines is generally relatively low.

The gravity separation process and flotation process are commonly used beneficiation methods in gold mines. Most gold mines in China use the above methods to extract gold, and there have been significant improvements in gold ore processing technology and equipment. The current mainstream process flow chart for gold ore beneficiation generally uses gold ore beneficiation equipment to crush, then ball mills to crush, and then gravity and flotation processes to extract the concentrate and tailings, followed by chemical methods and smelting. The product will become finished gold.

2、 Principle of steps

1. After the original ore is crushed in the front section, it enters the double vibration screening. The upper layer product is further crushed and then combined with the middle layer product for the second section crushing. The second section crushed product returns to the front section crushed product for screening.

2. The screened products are ground by the front stage ball mill and form a closed circuit grinding with the grading mechanism. The grading overflow is classified by the cyclone and then enters the second stage ball mill for further grinding, forming a closed circuit grinding with the cyclone.

3. The rotary overflow is first subject to preferential flotation. Its foam products are subject to secondary cleaning, and the tertiary cleaning is compared to become concentrate products. The tailings after preferential flotation go through the selection process of primary roughing, primary cleaning, secondary cleaning, tertiary cleaning, primary cleaning, etc. The tailings after primary cleaning and the foam products after primary cleaning enter the rotary products for re classification and re selection. The secondary cleaning and primary cleaning constitute closed circuit selection, Three rounds of selection and two rounds of selection constitute a closed loop selection.

3、 Process

1. Crushing and grinding process

The crushing process of gold placer beneficiation often uses a jaw crusher for coarse crushing, a standard cone crusher for crushing, and a short head cone crusher and a pair of roller crusher for fine crushing. Small and medium-sized gold concentrators often use a two-stage closed circuit crushing process, while large gold concentrators use a three-stage closed circuit crushing process. In order to improve production and the utilization coefficient of the gold ore beneficiation process, the beneficiation plant generally follows the principle of more crushing and less grinding, reducing the grinding particle size.

2. Re-selection process

Gold placer beneficiation method Gravity beneficiation process is a method of beneficiation based on Density contrast of minerals. The main beneficiation equipment for gold mines includes chutes, shakers, jigs, and short cone cyclones.

3. Flotation process

80% of the country's gold concentrators use the flotation process of gold ore beneficiation for gold separation, and the produced concentrate is mostly sent to non-ferrous smelters for treatment. With the continuous development of cyanide based gold extraction, in order to improve economic benefits and reduce concentrate transportation losses, enterprises often use on-site treatment. The flotation method in the beneficiation process of gold mines has developed rapidly and occupies an important position in gold beneficiation production.

4. Chemical selection process

The current flowsheet separation methods for gold ore beneficiation mainly include mercury mixing method and cyanide method. The mixed mercury method is an ancient gold extraction process that is both simple and economical, suitable for the recovery and utilization of coarse single gold. However, the flowsheet separation method of gold beneficiation has caused great environmental pollution, gradually being replaced by gravity separation, flotation, and cyanide methods. The cyanide extraction process includes cyanide extraction, washing and filtration of leaching pulp, extraction of gold from cyanide solution or cyanide pulp, and smelting of finished products.

5. Smelting process

Smelting is the subsequent process of extracting gold, divided into rough refining and refining. The development of gold smelting in China is rapid, and traditional crucible smelting is often used to produce high-quality gold, or to send it to non-ferrous metal smelters for processing and refining of finished gold.

The heap leaching process of the beneficiation process for gold mines.

In China's gold mine resources, low-grade oxidized ore accounts for a certain proportion. The conventional cyanide method for extracting metals from such ore is not cost-effective, but the use of stacking production technology has economic benefits.

4、 Beneficiation method

The beneficiation method of gold ore is to use the gold production line beneficiation technology of gold ore processing in order to obtain high recovery indicators of gold ore. The equipment and methods used in the gold ore beneficiation production line must conform to the properties of the gold ore, fully utilize resources, and reduce losses during the gold ore enrichment process.

Firstly, the gravity separation method for gold placer beneficiation.

Gravity separation is a commonly used beneficiation process in gold ore beneficiation methods, and the combination of gravity separation flotation magnetic separation process is also a favored beneficiation process by major gold ore beneficiation equipment manufacturers. The sand gold beneficiation equipment has the advantages of simple operation, low investment, low power consumption, and early recovery of gold ore. However, the disadvantage is that the recovery effect of fine gold is poor, so the sand gold beneficiation method is rarely used separately for gold ore beneficiation. The flotation cyanide process is often used to treat fine gold ore, which can directly produce high-quality gold, save gold concentrate losses and freight costs, and improve the economic benefits of material selection manufacturers. Gravity beneficiation is a method of separating ores according to Density contrast of minerals, which plays an important role in modern beneficiation. The main beneficiation equipment for gold mines includes chutes, shakers, knockout machines, and short cone cyclones.

Secondly, the flotation of gold placer beneficiation methods.

80% of domestic gold concentrators use flotation method for gold separation, and the produced concentrate is mostly sent to non-ferrous smelters for treatment. With the continuous development of cyanide based gold extraction and the efforts of enterprises to improve economic benefits and reduce concentrate transportation losses, the product structure has undergone significant changes. Many of them use on-site treatment (which is also due to conflicts and pricing issues between beneficiation and metallurgy, forcing mines to handle on site), resulting in significant development of the flotation process for gold ore beneficiation methods and occupying a significant position in gold beneficiation production. 98 types of gold and gold-bearing minerals have been discovered, with only 47 commonly found and only over 10 minerals directly utilized in industry. There are nearly 38 types of gold bearing substances in China, and the gold content is generally low.

Free design solution

Free design solution

24-hour engineer dispatch

24-hour engineer dispatch

In order to better serve you, we can leave your needs here, such as handling materials, production capacity, and finished product requirements. A professional product manager will reply to you!

Copyright: Jinqiang Mining Machinery

quotes and solutions

+8619870423316