quotes and solutions

+8619870423316

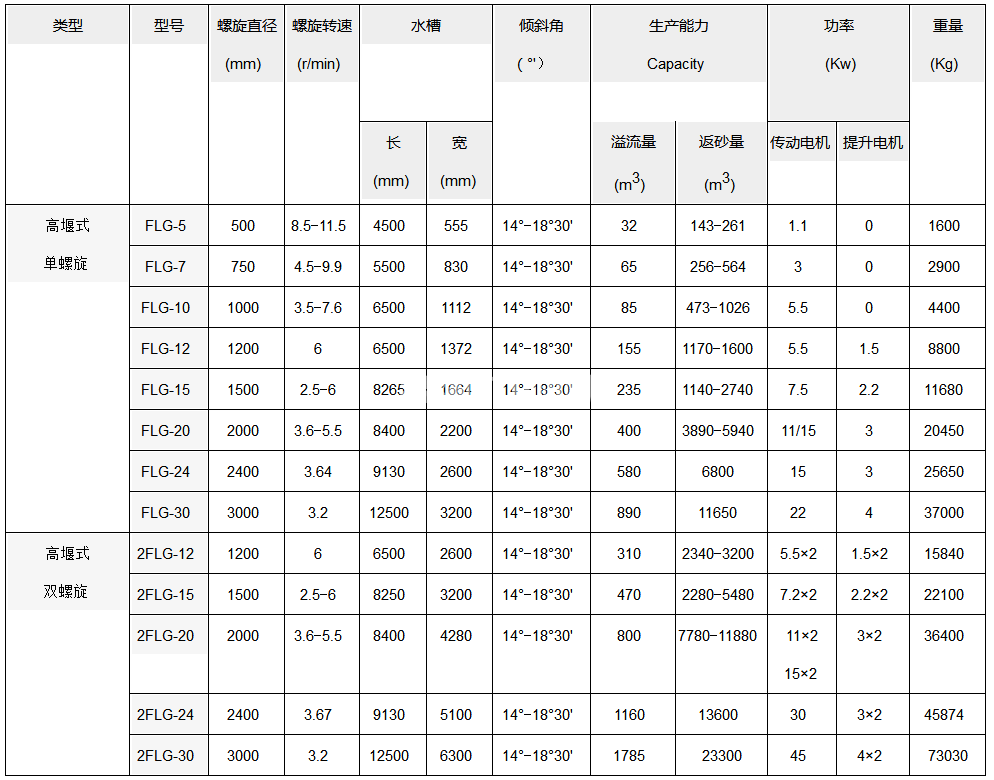

productivity:15-200t/h

Processing materials:It can be combined with a ball mill to form a closed circuit circulation path and split flow separation of ore sand, or used in gravity beneficiation plants to classify ore sand and fine mud.

Application scope:0-350mm

Feed particle size:0-350mm

Equipment processing capacity:15-200t/h

Production materials:It can be combined with a ball mill to form a closed circuit circulation path and split flow separation of ore sand, or used in gravity beneficiation plants to classify ore sand and fine mud.

1、 Introduction

Spiral classifier is used in mining plants to form a cable digital television classifier with a powder mill. It must have an organization to improve the transportation of settling sand, so this type of classifier is called a mechanical equipment classifier. In fact, the entire classification process is still carried out based on the settling speed of particles.

2、 Working principle

The spiral classifier is not only used as an auxiliary machine for grinding to carry out pre grading and inspection grading, but also sometimes used for washing clay containing iron ore and for desliming and drying the ore. According to the different ways of transporting sand settling machinery and equipment, the maximum spiral classifier can be divided into single spiral classifier, rake classifier, and floating groove classifier. Among them, the single screw classifier has a simple structure and convenient practical operation. The classification groove has a large oblique angle of view, which is conducive to automatic outflow connection with the powder mill, so it is widely used. Although other types of classifiers are still used in China, their production and manufacturing have been discontinued. The appearance design of the spiral classifier is a rectangular frame with a sloping groove, and the bottom end is semi circular. The groove body is equipped with one or two longitudinal axes, and spiral leaves are continuously installed along the axis length. Use the upper transmission mechanism to push the spiral shaft to rotate. If it is a double helix, it appears from the top that the spiral leaves rotate outward. The coal slurry is fed in from the side of the tank. Generate a foundation settlement grading surface below the groove. Coarse particles settle at the bottom of the trough and are then spirally guided upwards to be discharged. During the entire transportation process, they undergo dehydration. Fine particles that have not yet settled on the foundation are discharged from the surface coal slurry flow belt through overflow weirs. The entire grading process is basically consistent with that in the mud hopper. There is an architecture below the grading slot. The upper load-bearing beam of the structure is equipped with lifting equipment to adjust the distance between the spiral leaves and the bottom of the groove, and to extend the spiral shaft during parking to avoid stone and sand accumulation burying the spiral leaves.

3、 Classification

The liquid content of the maximum spiral classifier can be divided into two types: high weir type and submerged type (also known as submerged type). The overflow weir of the high weir single spiral classifier is higher than the management center of the lower spiral shaft and smaller than the inner edge of the spiral leaf. The length of the grading liquid level is not large, and the liquid level can immediately feel the stirring effect on the spiral leaves, so it is suitable for coarse grading, and the grading particle size distribution is more than 0.15mm. The spiral leaves at the bottom of the immersion classifier completely infiltrate below the liquid level. The total classification area is large and stable, suitable for fine sand classification, and the classification particle size is distributed below 0.15mm. The overflow production efficiency of the maximum spiral classifier is relatively high. In addition, there is also a low weir type spiral classifier, which has a classification liquid level lower than the lower spiral rolling bearing. The liquid level is not large, and the mixing efficiency is high. It is mainly used for washing sand and gravel.

Free design solution

Free design solution

24-hour engineer dispatch

24-hour engineer dispatch

In order to better serve you, we can leave your needs here, such as handling materials, production capacity, and finished product requirements. A professional product manager will reply to you!

Copyright: Jinqiang Mining Machinery

quotes and solutions

+8619870423316