quotes and solutions

+8619870423316

productivity:≤542m3/h

Processing materials:Classification equipment used for accelerating the sedimentation of mineral particles such as kaolin, quartz, potassium sodium feldspar, etc

Application scope:0.3-16mm

Feed particle size:0.3-16mm

Equipment processing capacity:≤542m3/h

Production materials:Classification equipment used for accelerating the sedimentation of mineral particles such as kaolin, quartz, potassium sodium feldspar, etc

1、 Introduction

Hydrocyclone is a kind of equipment used to separate and remove heavy coarse sand and other substances in sewage. Sometimes also used for mud dewatering. There are two types: pressure type and gravity type, often made of circular cylindrical structures or metal pipes. Water enters through the upper part of a structure (or metal tube) along a tangent line through pressure or gravity. Under the action of centrifugal force, coarse and heavy particulate matter is thrown towards the wall of the vessel and rotated downwards to discharge together with the formed thick liquid. The smaller particulate matter is rotated to a certain extent, although it is discharged by a secondary upward vortex.

2、 Structural composition

The upper part is conical. A feeding pipe is installed on the cylindrical cylinder in a tangential direction to the cylinder wall. The upper part of the cone is equipped with a central overflow pipe connected to the cylindrical part. The upper end of the overflow pipe is connected to the external pipeline through a buffer chamber or directly to discharge the overflow. A sand settling nozzle is installed at the bottom of the cone to discharge coarse sand. In order to reduce wear, wear-resistant rubber or wear-resistant materials such as Diabase, cast stone and silicon carbide can be lined at the feed mouth, grit nozzle and the inner wall of the cylinder.

3、 Working principle

When the slurry is pumped into the cylinder with a sand pump (or height difference) at a certain pressure (usually 0.5-2.5 kg/cm) and a flow rate (about 5-12 meters/second) along the tangent direction through the feeding pipe, the slurry rotates rapidly along the cylinder wall, generating a large centrifugal force. Under the action of centrifugal force and gravity, thicker and heavier ore particles are thrown towards the wall of the device, moving downward along the trajectory of the spiral line and discharged by the discharge nozzle at the lower part of the cone, while finer ore particles form an internal spiral upward slurry flow with water at the center of the cone and are discharged through the overflow pipe.

4、 Advantages

1. No moving parts, simple construction;

2. The production capacity per unit volume is relatively large and occupies a small area;

3. High classification efficiency (up to 80%~90%) and fine classification particle size;

4. Low cost and low material consumption.

5、 Application

Hydrocyclone has been widely used in the mineral processing technology of major metal mines. Mainly reflected in the following assignments:

1. One stage closed circuit grinding classification

2. Two-stage closed circuit grinding classification

3. Concentrate regrinding and grading

4. Desliming of raw ore before and after beneficiation

5. Daming and backfilling of tailings

6、 Precautions for use

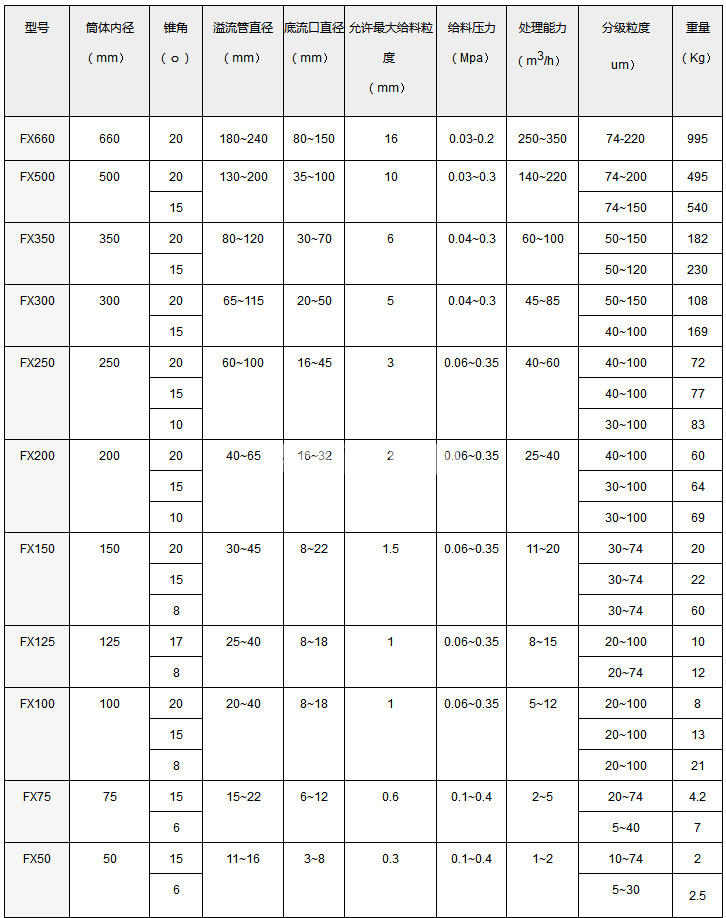

In a closed circuit grinding and classification system composed of a section mill, it has higher classification efficiency and finer overflow fineness at higher feed concentration. The classification efficiency is 5-10% higher than the commonly used spiral classifier, which is conducive to improving the utilization coefficient of the mill. The correct selection of appropriate specifications and models of hydrocyclones based on the requirements of grinding processing capacity, overflow fineness, and sediment concentration is a prerequisite for achieving optimal working conditions. We can provide users with single machine, parallel unit, or series unit.

When the tailings from the beneficiation plant are sent to the tailings pond for treatment, fine sand that is too small in the tailings should not be used as a material for tailings dam construction. After using a cyclone for classification, the coarse tailings remain in the dam body, while the fine tailings move towards the tail of the tailings pond. The fine slurry also naturally grades during the flow process, and the thin and fine tailings also naturally grade during the flow process. There is a clear water area at the tail of the tailings pond that can be used as return water. In the full tail filling process, a cyclone is used for pre classification and concentration to separate most of the coarse particles in advance, reducing the load on the subsequent filter and achieving better results. The use of a cyclone to complete dam construction and filling operations can solve problems such as tailings dam leakage, beach collapse, and excessive external drainage, and can achieve significant economic and social benefits.

Free design solution

Free design solution

24-hour engineer dispatch

24-hour engineer dispatch

In order to better serve you, we can leave your needs here, such as handling materials, production capacity, and finished product requirements. A professional product manager will reply to you!

Copyright: Jinqiang Mining Machinery

quotes and solutions

+8619870423316