quotes and solutions

+8619870423316

productivity:8-800m3/h

Processing materials:River pebbles, granite, basalt, iron ore, limestone, quartz, coal gangue, construction waste, etc

Application scope:<400mm

Feed particle size:<400mm

Equipment processing capacity:8-800m3/h

Production materials:River pebbles, granite, basalt, iron ore, limestone, quartz, coal gangue, construction waste, etc

1、 Introduction

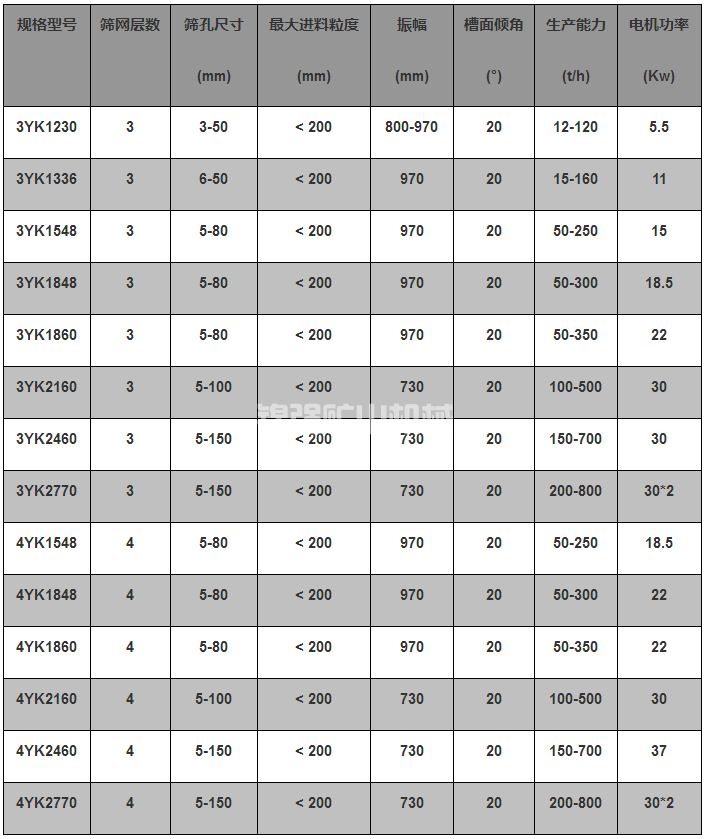

The circular vibrating screen for mining is a type of vibrating screen with circular vibration and double layers, commonly known as a circular vibrating screen. There are two key types of mining circular vibrating screens produced by Jinqiang: YA mining circular vibrating screen and YK mining circular vibrating screen. YA heavy circular vibrating screen is a universal and standardized mining circular vibrating screen equipment independently developed by our company, which belongs to the excitation force caused by axial force. YK heavy circular vibrating screen is a mining circular vibrating screen that is expanded from the YA type circular vibrating screen, which belongs to the excitation force caused by block axial force, The two commodities can meet the requirements of screening high efficiency, long life and no plugging, and are widely used in the classification of raw materials in the fields of mineral processing plants, mineral processing, decorative building materials, power engineering, chemical plants, etc.

2、 Working principle

The vibrator of the mining circular vibrating screen is installed on the baffle of the circular vibrating screen box. The motor drives the exciter's axial force block to run at high speed through a triangular belt. The running axial force block causes a very large centrifugal inertia moment, driving the screen box to cause a certain amplitude of circular fitness movement. The raw materials on the surface of the skewed screen are subjected to the momentum moment sent by the screen box, resulting in continuous throwing fitness movement throughout the entire process, The fine particles lower than the round hole sieve are screened according to the stainless steel screen, so as to achieve the goal of grading. The adjustment of the inclination angle of the screen surface can be achieved by changing the aspect ratio of the torsion spring rubber support.

3、 Application industry

Aluminum oxide powder, lead powder, copper filings, alloy powder, grinding paste, electrolytic nickel powder, welding wire powder, iron ore, Manganese dioxide, Electropermanent magnet materials, refractory insulation materials, porcelain clay, lime powder, aluminum oxide, heavy calcium carbonate, quartz sand, etc.

4、 Equipment structure

The heavy-duty circular vibrating screen is composed of an exciter, a screen box, a stainless steel screen, a vibrator, vibration reduction equipment, a base, and supporting equipment.

Screen box: It is made of aluminum profiles welded or riveted by electric welding or riveting, selected from the screen frame, screen powder, and clamping equipment.

Exciter: The heavy-duty circular vibrating screen uses a dual axis vibrator.

Support point equipment: mainly used to support the elastic components of the screen box, there are two types: suspended and vertical.

Damping equipment: Common types include compression springs, torsion springs, and rubber shock absorbers.

Transmission system: Generally, a V-belt transmission system is used, which is easy to organize and can freely select the speed of the vibrator.

Free design solution

Free design solution

24-hour engineer dispatch

24-hour engineer dispatch

In order to better serve you, we can leave your needs here, such as handling materials, production capacity, and finished product requirements. A professional product manager will reply to you!

Copyright: Jinqiang Mining Machinery

quotes and solutions

+8619870423316