quotes and solutions

+8619870423316

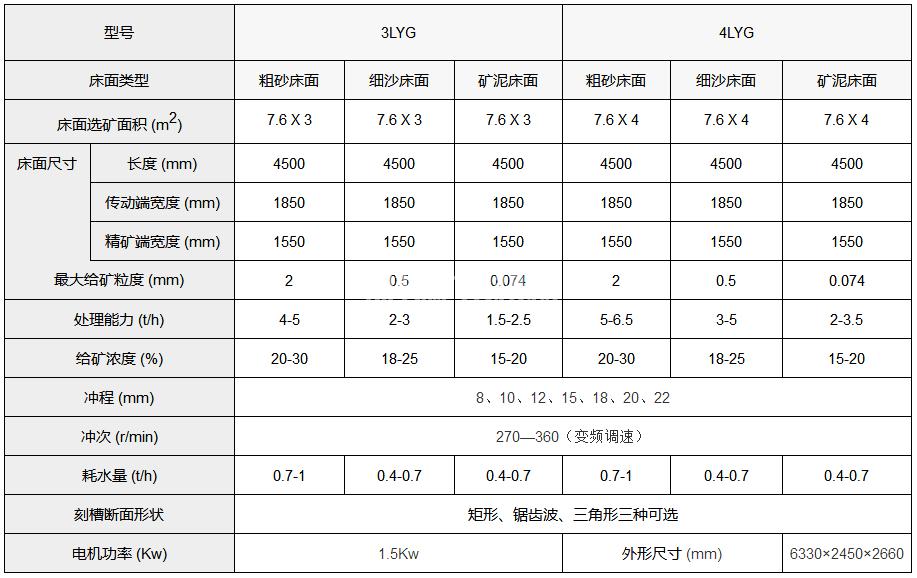

productivity:1.5-6.5t/h

Processing materials:Widely used for the separation of rare and precious metals such as tungsten, tin, tantalum, niobium, iron, manganese, chromium, titanium, bismuth, lead, gold, etc., as well as in coal mines

Application scope:0.074-2mm

Feed particle size:0.074-2mm

Equipment processing capacity:1.5-6.5t/h

Production materials:Widely used for the separation of rare and precious metals such as tungsten, tin, tantalum, niobium, iron, manganese, chromium, titanium, bismuth, lead, gold, etc., as well as in coal mines

1、 Overview

Multi layer shaking table is one of the key mechanical equipment for gravity beneficiation in mining machinery and equipment. Suspended multi layer shaking table is commonly used to separate tungsten, tin, tantalum, niobium, iron, manganese, chromium, titanium, bismuth, lead, gold and other non-ferrous and precious metal mines, and can also be used in the coal mining industry. The suspended multi-layer beneficiation shaker can be used for different operations such as roughing, optimization and scavenging, and for sorting coarse sand (2-0.5mm), fine sand (0.5-0.074mm) and mineral mud (-0.074) with different particle size distribution. The suspended multi-layer ore dressing shaker can also be used to separate iron, manganese ore, and coal. When solving the problem of tungsten, tin and other iron ores, the reasonable purchase particle size distribution range of the shaker is 2-0.022mm.

2、 Advantages and Features

1. The bed structure of the inertia force bedroom is appropriate, and the vertical force is self phase. There is no vertical excitation force, so it does not cause vertical flutter. It can be installed on the concrete floor slab of high-rise residential buildings or on the support frame;

2 suspension structure, with minimal friction function loss, environmentally friendly, energy-saving, and shock-absorbing, with no heavy base, fast and convenient installation;

3. The suspended multi-layer rocking bed adopts a fiberglass anti-corrosion bed body with wear-resistant layer bed strips, which is wear-resistant, moisture-proof, anti cracking, anti-corrosion, small deformation, less maintenance, and has a long service life;

4.The 4 bed bodies are installed in layers on a unified bed board, which is easy to install and remove, improving the output of the enterprise's land occupation. Replacing different balance weights can change the four stroke of the shaking table;

5 The frequency converter is selected, which can easily change the stroke times to incorporate raw materials with different particle size distribution and characteristics.

3、 Equipment structure

The suspended multi-layer shaking table has a high silver ore ratio, high sorting efficiency, and is very easy to take care of, which is conducive to adjusting the four stroke. By changing the horizontal inclination and four stroke, the bed can still maintain balanced operation. The bullet yellow is placed on the box body, with a compact structure, and the final titanium concentrate and tailings pond can be obtained successively. The suspended multi-layer rocking bed equipment is mainly composed of eight parts, including a bedroom bed, an electric motor, a slope adjuster, a bed body, a mining trough, a stainless steel sink, a strip and its air intake system.

The external design of the suspended multi-layer beneficiation shaker bed is a right angled trapezoid. In the wooden framework, the blockboard is assembled along the oblique direction (45 degrees from the centerline) to form a plan. The bed body is divided into two types: painted gray grooved bed surface and vulcanized rubber bed body. The surface of the lacquer gray groove bed is used to select fine mud, while the vulcanized rubber bed body is used to select coarse ore. The bed used for selecting fine mud has a vertical inclination of 0.5 degrees up and down, while the shaker used for selecting coarse sand has a vertical inclination of 1-2 degrees and is raised at the end of the titanium concentrate. The size of the vertical inclination is adjusted by the anchor bolts on the support point organization.

4、 Working principle

The vertical repeated movement of the bed body of the suspended multi-layer shaking table equipment is completed based on the crank connecting rod transmission mechanism. The motor drives the engine crankshaft through a large belt pulley driven by a synchronous belt, and the remote rod moves up and down for fitness. When the remote rod moves down for fitness, the elbow plate promotes the rear wheel and reciprocating rod to move back, causing the spring to shrink. The bed body is connected by a connecting seat and a reciprocating rod, so at this time, the bed body is also engaged in a backward fitness exercise. When the remote rod is used for upward fitness exercise, it is promoted by the stretching force of the spring yellow, and the bed body moves forward with the fitness exercise.

During the forward fitness exercise period, the angle between the elbow plates changes from large to small, and the horizontal movement rate of the elbow plate nodes changes from small to large. Therefore, the forward fitness exercise of the bed body changes from slow to fast. On the contrary, when the bed body reverses, it changes from fast to slow, leading to differential fitness exercise. This ensures that the raw materials on the bed surface move forward and undergo proportional screening.

Free design solution

Free design solution

24-hour engineer dispatch

24-hour engineer dispatch

In order to better serve you, we can leave your needs here, such as handling materials, production capacity, and finished product requirements. A professional product manager will reply to you!

Copyright: Jinqiang Mining Machinery

quotes and solutions

+8619870423316