quotes and solutions

+8619870423316

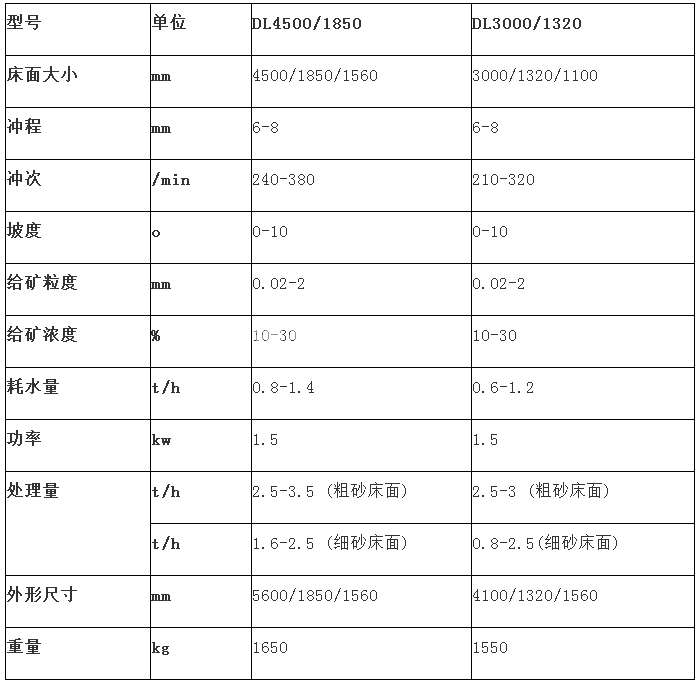

productivity:0.8-2.5t/h

Processing materials:Widely used in the separation of rare and precious metal ores, including tungsten, tin, tantalum, niobium, iron, manganese, chromium, titanium, bismuth, lead, gold, etc. In addition, it can also be us

Application scope:0.02-2mm

Feed particle size:0.02-2mm

Equipment processing capacity:0.8-2.5t/h

Production materials:Widely used in the separation of rare and precious metal ores, including tungsten, tin, tantalum, niobium, iron, manganese, chromium, titanium, bismuth, lead, gold, etc. In addition, it can also be us

1、 Introduction

The double-layer shaker table is a technological innovation product of the 6-S traditional single side shaker table. The 6-S double-layer shaker table has the advantages of small footprint, large output, energy conservation, environmental protection, and relatively low cost of machinery and equipment. It has high silver ore ratio and high sorting efficiency. The 6-S double-layer constant temperature shaker is very easy to take care of, which is conducive to adjusting four strokes, stroke, and other advantages. The 6s double-layer large shaking table can still maintain balanced bed operation when changing the horizontal inclination and four stroke. The bullet yellow is placed on the box body, with a compact structure, and can obtain the final titanium concentrate and tailings pond at once.

2、 Advantages and characteristics

The traditional 6S shaker table has a large land area, low output, and a large distribution of customer funds. Customers who need to apply the 6-S single sided shaker table are very distressed, but there is no stronger machinery, equipment, and methods to handle this problem. The release of the 6S double-layer mineral processing shaker has solved many difficulties in the entire application process of the 6-S single side shaker table. The 6S double-layer shaker table has the advantages of small footprint, large output, energy conservation, environmental protection, and relatively low cost of machinery and equipment. It has the advantages of high silver ore ratio, high sorting efficiency, and easy care, which is conducive to adjusting the four stroke and stroke speed. When changing the horizontal inclination and four stroke, the bed can still maintain balanced operation. The bullet yellow is placed on the box body, with a compact structure, and can obtain the final titanium concentrate and tailings pond at once.

3、 Product structure and materials

The 6S double-layer mineral processing shaker table is equipped with the same base as the 6-S large grain steel support frame shaker table. The two legs are placed on the large grain steel base, and the large grain steel thick steel plate is lifted and welded with the steel support frame to place the shaker bed. The shaker surface is selected to lift a bed body with the same specifications as the original bed body on the surface of the 6-S single sided shaker table. The left and right double layers are connected with thick steel plates to support points, with a spacing of 400mm and a free space of about 300mm. The bedroom bed still adopts a double crank rocker structure, with a yellow box on the rocker box. The engine crankshaft, support rod, yellow, remote rod and other components have correspondingly increased specifications and materials are more standardized. The bed is made of fiberglass anti-corrosion material, and the specifications of the upper and lower layers of the 6S double-layer beneficiation constant temperature shaker are 1823 * 1558 * 4520. The upper and lower bed bodies use the same set of slope adjustment equipment as the lower bed body, supported by a rocking elbow plate. The rotation diagonal of the adjustable seat plate and base is expanded to 545mm to incorporate the arc support point rotation center point and the traction belt screw management center on the same parallel line.

4、 Application scope

Widely used in the separation of tungsten, tin, tantalum, niobium, gold and other non-ferrous and precious metal ores. It can be used for different work such as roughing and sweeping, to separate coarse sand (2-0.5mm), fine sand (0.5-0.074mm) and mineral mud (-0.074) with different particle size distribution. The 6S double layer ore dressing shaker table can also be used to separate iron, manganese ore, and coal. When solving the problem of tungsten, tin and other iron ores, the reasonable purchase particle size distribution range of the shaker table is 2-0.22mm.

Free design solution

Free design solution

24-hour engineer dispatch

24-hour engineer dispatch

In order to better serve you, we can leave your needs here, such as handling materials, production capacity, and finished product requirements. A professional product manager will reply to you!

Copyright: Jinqiang Mining Machinery

quotes and solutions

+8619870423316