quotes and solutions

+8619870423316

productivity:0.2-10t/h

Processing materials:Minerals with specific gravity differences, such as tungsten, tin, tantalum, titanium, gold, zirconium, niobium, etc

Application scope:0.02-2mm

Feed particle size:0.02-2mm

Equipment processing capacity:0.2-10t/h

Production materials:Minerals with specific gravity differences, such as tungsten, tin, tantalum, titanium, gold, zirconium, niobium, etc

1、 Introduction

The rotary chute is a re concentration machine and equipment widely used for screening mineral processing materials. In terms of iron ore materials, 0.2~0.03mm particle size distribution can be reasonably purchased. Mineral particles suffer the effects of force, Centripetal force, hydrodynamic working pressure and sliding friction force on the surface of the rotary chute leaves, and then carry out hierarchical zonation and finally obtain screening. Over the years, practical experience in the selection of rotating chutes for iron ore materials has proven that there are also some rich cohesive layers of iron ore materials that have already been individually dissociated, which are either lost in tailings ponds or returned to the regrinding control circuit and become overground particles that cannot be purchased. Therefore, the general rotating spiral chute must be improved to improve the sorting efficiency, and to achieve the goal of improving the efficiency of waste metal recycling and high yield, quality and efficiency.

2、 Structure and Principle

The fiberglass rotary spiral chute is composed of six parts: a feeding homogenizer, a feeding trough, a spiral chute, a commodity extraction trough, a commodity gathering hopper, and a trough support frame (including a cross or triangular frame). The spiral groove formed by connecting spiral pieces is a key component. The rotating chute is made of fiberglass anti-corrosion (fiberglass elastomer material) and connected together with anchor bolts. The selection surface of the rotating spiral chute has a wear-resistant layer of prefabricated components. It has the advantages of lightweight, sturdy, and durable daily necessities. The upper side of the spiral groove is equipped with a multi tube feeding homogenizer to evenly distribute the ore, making it easy to operate. The ore separator is randomly placed on the cross (or tripod) of the support table. The evenly divided coal slurry is slowly fed to the surface of the spiral groove by the feeding groove at the head end of the spiral groove for screening. The tail of the rotating spiral chute is installed in a valve block type new product extraction tank, and the screened new products are divided into three (or four) new products according to grade along the axis. Change the total extraction width of each new product by adjusting the position of the valve block. The new product gathering bucket is a circular tube that gathers and guides the extracted double head ore flow separately. The cross-section of the grooved spiral chute and the tangent slope transformation of the curve are particularly suitable for the selection of fine particle raw materials. The rotating spiral chute has the advantages of simple structure, no fitness sports parts, light weight, low noise, and convenient installation and maintenance.

The newly developed and wedge-shaped rotary chute leaves are improved with the way of spreading grooves in the rice washing basin by referring to the mechanism of the horizontal grooves on the surface of the shaker bed. The wedge-shaped grooves are carved on the leaves of the rotary spiral chute. The wedge-shaped grooves have Inscribed circle grooves and guiding grooves. The sun flower can not only improve the pulsating effect of running water, but also move heavy minerals along the groove to the inside by relying on the guiding grooves, Beneficial for improving the utilization rate of iron ore materials.

3、 Main parameters

(1) Leaf characteristics. The wedge-shaped rotating spiral chute leaf is a basic design of a general glossy leaf, designed according to the leaf cross-section (Y=10X3) of a general rotating spiral chute of $1200Mm * 720Mm. The only difference is that the wedge-shaped groove is engraved on the leaf. The wedge-shaped slope gradually rises inward along the axis into an H-shaped shape. Due to the gradual thickening of the coal slurry flow film on the surface of the rotating spiral chute leaf groove along the axial direction, the height to width ratio of the wedge-shaped groove in the design scheme increases by 1.5, 2.0, and 3.0 Mm from the interval between the inward and outward types.

(2) There are various methods for assembling H-shaped and glossy leaves. The wedge-shaped groove spiral chute used in industrial production experiments is composed of two H-shaped leaves at the top and two glossy leaves at the bottom, P, assembled into a 2HP shape.

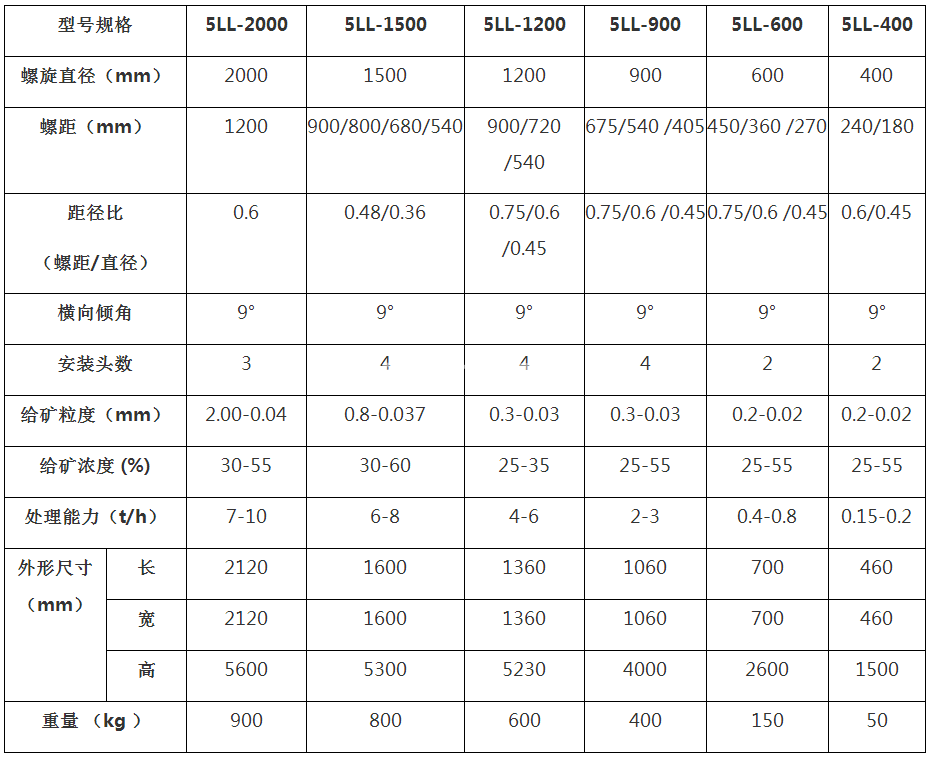

(3) The main parameters of the wedge-shaped groove spiral chute.

① Number and number of circles: Two heads are installed during laboratory experiments, and four heads are installed during industrial production experiments. Each head is composed of four leaves, resulting in a total of four circles;

② Spiral diameter D: commonly used in industrial production with a diameter of D=1200Mm;

③ Vertical inclination angle of tooth pitch S: The universal tooth pitch in industrial production of tooth pitch mining is S=720Mm. Calculate tga=S (X.D) using the formula, and obtain the vertical inclination angle of the edge&=arctgS/(X.D)=arctg720 * (3.14 * 1.2)=10.82. The vertical inclination angle gradually expands from the edge to the inner edge. The vertical inclination angle in the middle is 18, and the inner edge is 46.2;

④ Cross section appearance and transverse inclination angle B of the leaves: The leaves are selected using the cross-sectional appearance specified by the cubic meter parabolic equation Y=10X1/3 or x=0.001Y3. The horizontal tilt angle is 9.

4、 Data comparison explanation

(1) The experimental results of comparing the industrial production of the wedge-shaped rotating spiral chute composed of 2H2P and the general spiral chute made of 4P show that under the conditions of similar ore feeding standards and titanium concentrate grade, the 2H2P type has a 3.97 percentage increase in waste metal recovery efficiency compared to the 4P type, a 2.81 percentage increase in beneficiation plant efficiency, and a 2.29 percentage increase in concentrate resource yield.

(2) The rotating spiral chute alleviates the dehydration condition on the surface of the leaf chute compared to the general spiral chute, and changes the concentration values throughout. When the concentration values of the titanium concentrate belt are similar, the average concentration value of the tailings pond belt in the middle ore belt is above 5% lower, which is beneficial for the loosening of raw materials and the promotion of mineral quality acquisition.

(3) The utilization ratio of each particle size distribution above the rotary chute+0.031mm is higher than that of the general spiral chute, while the utilization ratio of each material grade above the+0.056mm is more significant. Therefore, the rotating chute can be more integrated into the production process of stage grinding, size screening and re selection, reducing the overgrinding of iron ore materials and beneficial for improving the utilization rate of all metal materials.

Free design solution

Free design solution

24-hour engineer dispatch

24-hour engineer dispatch

In order to better serve you, we can leave your needs here, such as handling materials, production capacity, and finished product requirements. A professional product manager will reply to you!

Copyright: Jinqiang Mining Machinery

quotes and solutions

+8619870423316