quotes and solutions

+8619870423316

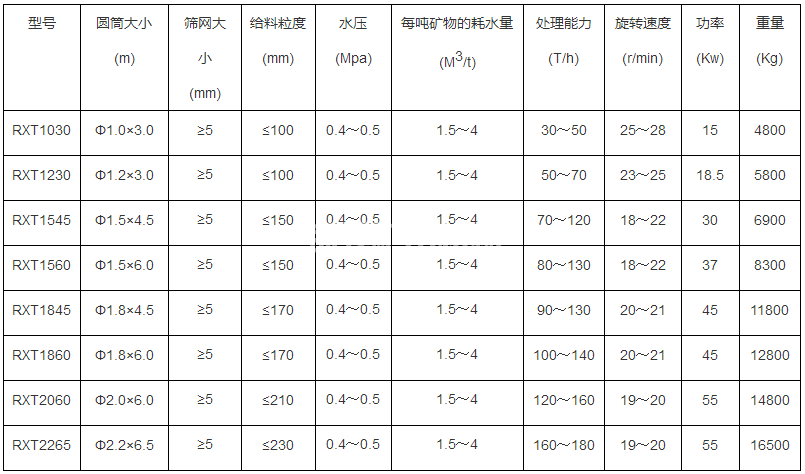

productivity:10-350t/h

Processing materials:Nickel ore, tungsten ore, crushed stone, river pebble, manganese ore, basalt, barite, granite, iron ore, limestone, ceramic particles, phosphate ore, gold mine, quartz stone, coal gangue, and various

Application scope:0-300mm

Feed particle size:0-300mm

Equipment processing capacity:10-350t/h

Production materials:Nickel ore, tungsten ore, crushed stone, river pebble, manganese ore, basalt, barite, granite, iron ore, limestone, ceramic particles, phosphate ore, gold mine, quartz stone, coal gangue, and various

1、 Introduction

The Drum ore washing machine, also known as the drum stone washing machine, is mainly used for manual desilting of stones with sand and stones below 80mm. It has the advantages of large feed particle size distribution, powder content of cleaned stone less than 0.5%, and moisture content less than 2%. The Drum ore washing machine equipment is no different from other washing machines except for its different structure. The Drum ore washing machine has a very high level of cleaning sand and gravel, and it has also been widely used in many stone production lines.

2、 Application scope

The Drum ore washing machine and equipment are key applications in many construction sites, such as construction sites, quarries, cement plants, and hydropower projects. It can also be used for the desilting and selection of sand and stone, as well as for the selection of iron ore. This drum stone washing machine is relatively similar to a spiral stone washing machine and has the advantages of large production capacity, low operating noise, and more convenient maintenance.

3、 Working principle

The raw materials fall vertically from the upper end of the equipment into the high-speed centrifugal impeller. Under the effect of rapid Centripetal force, they collide and break rapidly with another part of the raw materials flowing around the centrifugal impeller in an umbrella shape. After the raw materials collide with each other, they will collide and rub with each other for several times in the middle of the centrifugal impeller and the housing with the raw materials, and they will be discharged directly from the bottom, The cable digital TV cycle system is generated for several times, and the particle size distribution of finished products is regulated by the screening equipment.

4、 Advantages and characteristics

1. The output is large because the basic principle of sand washing in a Drum ore washing machine is not to use a bucket to retrieve ore;, As a result, its output has been greatly improved.

2. The higher energy utilization rate reduces the energy consumption damage caused by the wheel bucket during the entire process of improvement, making the kinetic energy more powerful and reasonably utilized.

3. Reduced the damage to some components, the sand washing machine does not need to lift the stainless steel screen, thus reducing the consumption of the stainless steel screen and increasing the service life of the machine equipment.

4. The actual cleaning effect is stronger. Compared with the single bucket wheel, the spiral sand washing machine takes a large amount of time and frequency for sand material to undergo rotary cleaning, resulting in a stronger cleaning effect.

Free design solution

Free design solution

24-hour engineer dispatch

24-hour engineer dispatch

In order to better serve you, we can leave your needs here, such as handling materials, production capacity, and finished product requirements. A professional product manager will reply to you!

Copyright: Jinqiang Mining Machinery

quotes and solutions

+8619870423316