quotes and solutions

+8619870423316

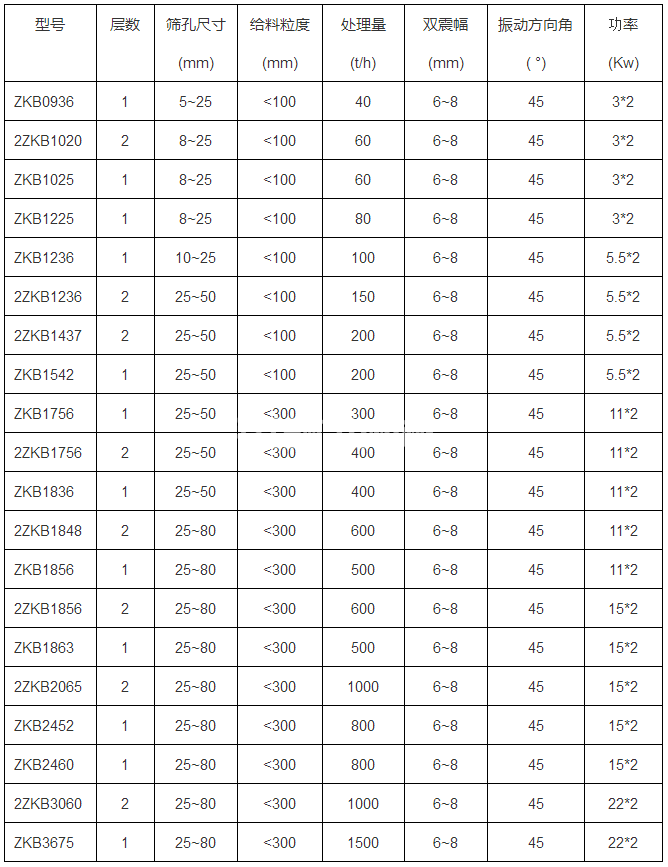

productivity:10-600t/h

Processing materials:Quartz stone, coal gangue, limestone, basalt, granite, construction waste, iron ore, river pebbles, etc

Application scope:<400mm

Feed particle size:<400mm

Equipment processing capacity:10-600t/h

Production materials:Quartz stone, coal gangue, limestone, basalt, granite, construction waste, iron ore, river pebbles, etc

1、 Working principle

The high-frequency linear vibrating screen equipment is driven by dual vibrators. When the two vibrators rotate in the same step and opposite direction, the excitation force caused by their axial force blocks collides with each other in the direction parallel to the centerline of the motor, and is stacked together in the direction perpendicular to the motor axis. Therefore, the trajectory of the screening machine is a parallel line. The two motor shafts have a tilt angle relative to the screen powder. Under the combined effect of the exciting force and the self force of raw materials, the raw materials are thrown up on the screen surface and move forward at a uniform speed in a straight line, thus achieving the goal of selecting and grading raw materials.

Using a vibration motor to excite vibration as the driving force for vibration, the raw materials are thrown onto the stainless steel screen mesh, while moving forward in a uniform linear motion. The raw materials are evenly fed from the vibration feeder to the feeding port of the screening equipment. The high-frequency linear vibration screen produces various specifications and models of screened materials and underscreened materials based on the double-layer stainless steel screen mesh, each discharged from its respective inlet and outlet.

2、 Classification

This machine is classified into high-frequency vibrating screens, linear vibrating screens, circular vibrating screens, etc.

3、 Application

High frequency linear vibrating screen equipment can also select and classify powdery and granular raw materials, and is widely used in plastics, wear-resistant materials, chemical plants, pharmaceuticals, decorative building materials, cereals, carbon plants, Manure and other fields.

4、 Characteristics

The high-frequency linear vibrating screen equipment can be used to complete automation technology work in the production line. It has the characteristics of low energy consumption, high efficiency, simple construction, easy maintenance, and fully enclosed structure for dust generation and dispersion. The maximum screen mesh is 400 mesh, and 7 kinds of raw materials with different particle size distribution can be screened.

Free design solution

Free design solution

24-hour engineer dispatch

24-hour engineer dispatch

In order to better serve you, we can leave your needs here, such as handling materials, production capacity, and finished product requirements. A professional product manager will reply to you!

Copyright: Jinqiang Mining Machinery

quotes and solutions

+8619870423316