quotes and solutions

+8619870423316

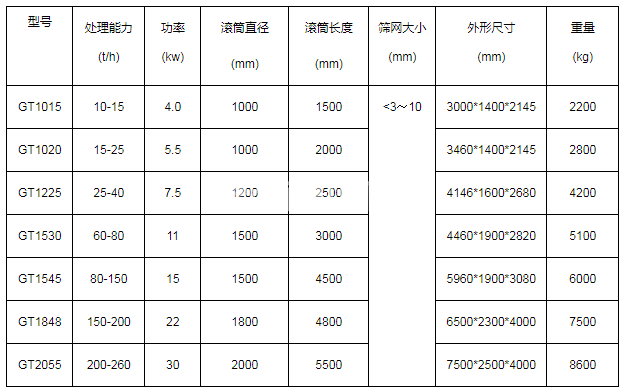

productivity:10-300t/h

Processing materials:Used for grading powdery materials, with good screening effect and customizable screening mesh and processing capacity

Application scope:0-150mm

Feed particle size:0-150mm

Equipment processing capacity:10-300t/h

Production materials:Used for grading powdery materials, with good screening effect and customizable screening mesh and processing capacity

1、 Introduction

The axial drum screen is suitable for screening materials of various properties, as well as damp and easily clogged materials such as coal, coke, and white ash. The maximum size of the product under the screen is 100mm, with a middle of 10-50mm and the smallest size up to≤ Below 3mm.

2、 Structure Description

1. Classified by size: small and medium-sized products with a central axis and large products without a central axis. Small and medium-sized models are equipped with cross backrest transmission for motors and reducers, while large models are equipped with gear ring transmission.

2. The screen body is a replaceable structure, which means that when the screen body is worn out and cannot be used, it can be disassembled and replaced as a whole. Standard spare parts are available in the factory.

3. The screen body and screen strip are made of wear-resistant materials, and users can repair and replace them themselves.

4. After grading, the raw materials are directly transported by a belt conveyor.

3、 Performance characteristics

1. Wide adaptability of materials

The drum screen is widely used for screening various materials, whether it is low-quality coal, coal slurry, coal smoke, or other types of materials, all of which are smoothly screened.

2. Simple and diverse feeding methods

The feeding port of the drum screen developed by our company can be designed according to the actual situation on site, whether it is a belt, funnel, or other feeding methods, without special measures,

All can be smoothly fed

3. High screening efficiency

The equipment can be equipped with a comb type cleaning mechanism, which can screen no matter how dirty or miscellaneous the material enters the screening cylinder during the screening process, thereby improving the screening efficiency of the equipment.

4. Large screen size, easy to scale

Under the same size, the circular area is larger than the area of other shapes, so the effective screening area is larger, allowing the material to fully contact the screen, resulting in a larger screening amount per unit time. Additionally, due to its simple structure, convenient layout, innovative and mature technology, it is easy to scale up.

5. Low self energy consumption

The motor power of the drum screening machine developed by our company is small, and the power consumption for processing the same amount of materials in the same time is half to one-third of that of other screening types.

Free design solution

Free design solution

24-hour engineer dispatch

24-hour engineer dispatch

In order to better serve you, we can leave your needs here, such as handling materials, production capacity, and finished product requirements. A professional product manager will reply to you!

Copyright: Jinqiang Mining Machinery

quotes and solutions

+8619870423316