quotes and solutions

+8619870423316

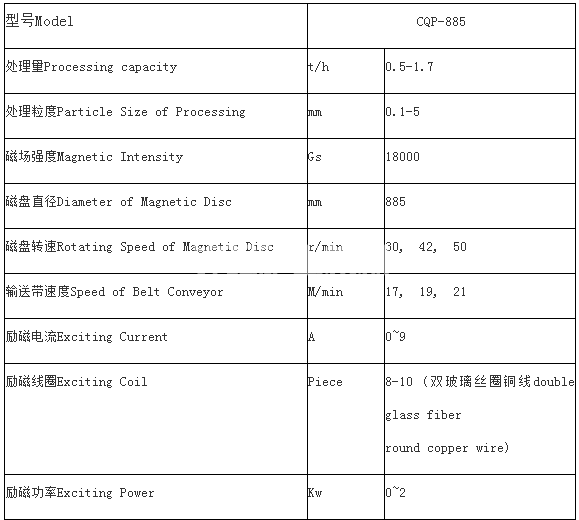

productivity:0.5-1.7t/h

Processing materials:Iron ore, ilmenite, chromite, pyrite, zircon, rutile, monazite, tungsten ore, tin ore, niobium ore, etc

Application scope:0.1-5mm

Feed particle size:0.1-5mm

Equipment processing capacity:0.5-1.7t/h

Production materials:Iron ore, ilmenite, chromite, pyrite, zircon, rutile, monazite, tungsten ore, tin ore, niobium ore, etc

1、 Introduction

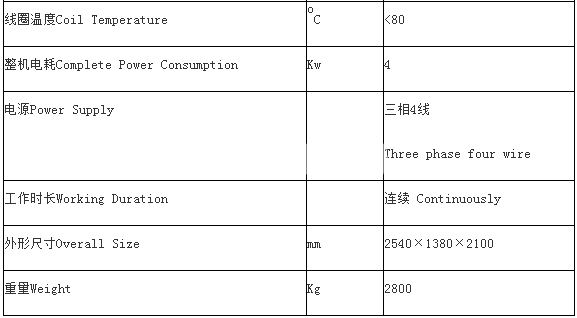

The single disk magnetic separator CQP-885 is a dry test magnetic separator. The magnetic system is manufactured from industrial production of electrical pure iron and high toughness wire wrapped copper core wire. The single disk magnetic separator has the following characteristics: electromagnetic field strength and large output. The single disk magnetic separator is suitable for manganese ore, Ilmenite, high tin tungsten ore, Rutile, garnet, tantalum niobium ore, Chromite, rare earth ore, monazite, zircon ore Screening and optimization of non-metallic materials for iron removal and weakly magnetic minerals.

2、 Structural characteristics

1. The single disc magnetic separator has stable characteristics, strong adaptability, and is easy to install, operate, and maintain.

2. The server is composed of feeding part, transmission system part and electromagnetic field part.

3. The electronic control system consists of a switching power supply, control, rectifier, and a part of the working label.

3、 Operating steps and common problems:

1. Dry raw materials are screened and loaded into the feeding bin. Particle size distribution regulations≤ 2mm

2. Adjust the working clearance of hard disk according to mineral separation, particle size distribution and regulations of concentrator

3. Close the knife switch to supply the switch power to the control panel

4. Turn on the motor and electromagnetic field power switch. Adjust the AC voltage regulator to the appropriate flow rate

5. Open the feeding gate valve to evenly distribute the raw materials onto the conveyor belt

6. Terminate feeding before shutting down the three disk magnetic separator

7. Common operational issues:

① The raw materials of the three disk magnetic separator contain magnetic minerals for a short period of time, and the feeding layer should be thinner to improve utilization efficiency; When there are many magnetic mineral components, the feeding layer can be thicker

② When the gap between hard drives is fixed during operation, changing the current size can adjust the magnetization intensity; When the current is constant, changing the current size can adjust the magnetization intensity; When the flow is constant, adjusting the gap during the operation of the hard drive can adjust the magnetization intensity

③ The three disk magnetic separator solves the problems of minerals with strong magnetic field and soft electromagnetic field, and solves the problems of minerals with weak magnetic field and extremely strong electromagnetic field for scanning work

④ The size of the clearance in hard disk operation depends on the particle size distribution of the raw materials to be solved and the working regulations; When solving coarse levels, it should be larger, and when solving fine levels, it should be smaller; Reduce the time and space gap during scanning to improve utilization, and increase the gap during optimization to enhance the selection of separated products and enhance the taste of magnetic products. However, at the same time, increase the current to compensate for the reduced magnetization caused by increasing the gap during operation

⑤ When the three disk magnetic separator is working, do not use special tools and objects for strong magnets near the magnetic system

Free design solution

Free design solution

24-hour engineer dispatch

24-hour engineer dispatch

In order to better serve you, we can leave your needs here, such as handling materials, production capacity, and finished product requirements. A professional product manager will reply to you!

Copyright: Jinqiang Mining Machinery

quotes and solutions

+8619870423316