quotes and solutions

+8619870423316

productivity:0.18-38m3/min

Processing materials:Non ferrous metals, non-metals, coal jadeite, talc, etc

Application scope:0.05mm-5mm

Feed particle size:0.05mm-5mm

Equipment processing capacity:0.18-38m3/min

Production materials:Non ferrous metals, non-metals, coal jadeite, talc, etc

1、 Introduction

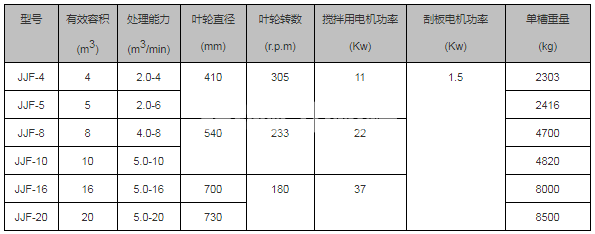

The JJF flotation machine is a self breathing mechanical stirring flotation machine independently developed by the Beijing Mining and Metallurgy Science Research General Hospital in China. The JJF flotation machine manufacturer's equipment is one of the most commonly used self breathing mechanical stirring flotation machines in China at present, with a single cell capacity of up to 200m3. The JJF flotation machine is used to select metal mines and mining enterprises with a wide range of gas injection requirements such as copper and molybdenum. JJF flotation machine has reasonable structure, reliable operation and stable operation, and its characteristics have reached the excellent level of overseas flotation machines. It is suitable for the separation of non-ferrous plates, Light metal and mining enterprises.

2、 Characteristics

1. Self priming gas;

2. The coal slurry circulation system has good characteristics;

3. The relative stability of respiratory volume;

4. Moderate compressive strength during mixing and excellent floatation of solid particles;

5. Stable liquid level and low output power consumption.

3、 Application scope

It can be widely used for the separation of nonferrous metals, Ferrous and non-metallic minerals, and is suitable for the roughing and scavenging operations of large and medium-sized flotation plants.

4、 Structural characteristics

1. Shallow groove type, small impeller diameter, low speed, and low power consumption;

2. The clearance between the impeller and stator is large, and the stator is a cylinder with elliptical holes, which is conducive to the mixing and dispersion of air and slurry;

3.The height of the stator is lower than that of the impeller, and the slurry circulation capacity is large, up to 2.5 times;

4. The umbrella shaped perforated dispersion cover of the stator can separate the vortex generated by the impeller from the foam layer, so that the pulp surface is stable.

5、 Model advantages

The JJF flotation machine uses the SF type flotation machine as the suction tank, which has dual functions of suction and flotation reagents. It forms a collaborative power generation unit with the JJF type flotation machine and is equipped horizontally, without the use of a foam pump. This solves the problem of using the JJF flotation machine to equip and use a foam pump step by step. For example, the SF type produced by Jinqiang Machinery as the suction tank and the JJF type as the DC cell in the collaborative flotation unit have large breathing capacity and low energy consumption.

The SF and JJF flotation machine collaborative generator set has been used in the production and manufacturing of a certain mining plant. Practical experience has proven that the research and development of generator sets has been successful, and the economic benefits are significant. The generator set is equipped at a standard level, without the use of a saturated foam pump, simplifying the preparation of flotation reagent steps, providing a new plan for the selection of flotation reagent machinery and equipment, especially providing comprehensive work experience for the upgrading of flotation reagent machinery and equipment in old beneficiation plants.

6、 Performance advantages

1. The slurry circulation capacity is large, up to 2.5 times, which is conducive to the mineralization of minerals, drugs, and gas;

2. Large inhalation volume and good dispersion effect;

3. Moderate stirring degree, good suspension of solid particles, no settling in the tank, and no need for ore drawing when parking;

4. The particle size range that can be processed is wide, and the beneficiation recovery rate is high.

Free design solution

Free design solution

24-hour engineer dispatch

24-hour engineer dispatch

In order to better serve you, we can leave your needs here, such as handling materials, production capacity, and finished product requirements. A professional product manager will reply to you!

Copyright: Jinqiang Mining Machinery

quotes and solutions

+8619870423316