quotes and solutions

+8619870423316

productivity:1-1000t/h

Processing materials:River pebbles, granite, basalt, iron ore, limestone, quartz, coal gangue, construction waste, etc

Application scope:≤1200mm

Feed particle size:≤1200mm

Equipment processing capacity:1-1000t/h

Production materials:River pebbles, granite, basalt, iron ore, limestone, quartz, coal gangue, construction waste, etc

1、 Introduction

The Ebo crusher is also known as Ebo, Ebo machine, and Ebo crusher, also known as Laohukou. In mining plants, it is often used as a mechanical equipment for extruding and crushing various raw materials with a tensile strength not exceeding 320Mpa. The Ebo crusher has the characteristics of large crushing ratio, uniform distribution of commodity particle size, simple structure, reliable operation, etc. It is widely used in mining, smelting plants, decorative building materials, roads, railway lines, water conservancy projects, chemical engineering and many other units.

2、 Working principle

The entire process of crushing iron ore by the EB crusher involves adding raw materials to the EB crusher chamber (an indoor space composed of fixed and movable jaw plates). Due to the regular reciprocating shaking of the movable jaw plate, when the movable jaw plate approaches the fixed jaw plate, the raw materials are crushed due to damage, fracture, and bending. When the movable jaw plate leaves the fixed jaw plate, the raw materials that have been crushed to below the specifications of the ore discharge port are discharged from the lower ore discharge port by their own weight. The raw material located at the upper end of the crushing chamber, which has not yet been crushed to a sufficient size, is once again crushed due to the effect of the jaw plate as it lands below the crushing chamber.

3、 Advantages and Features

1. The EB machine has a simple structure, is very easy to operate, and is convenient for maintenance. The shutdown maintenance time is greatly shortened;

2. The 2 moving jaw plate is composed of high-quality cast steel parts, and the ultra heavy camshaft is produced and processed using forged blanks, which promotes the extraordinary reliability of the EBO machine server;

3. The EB machine adopts higher and more durable camshaft rolling bearings, which enable the EB machine to have higher load-bearing capacity.

4、 Application

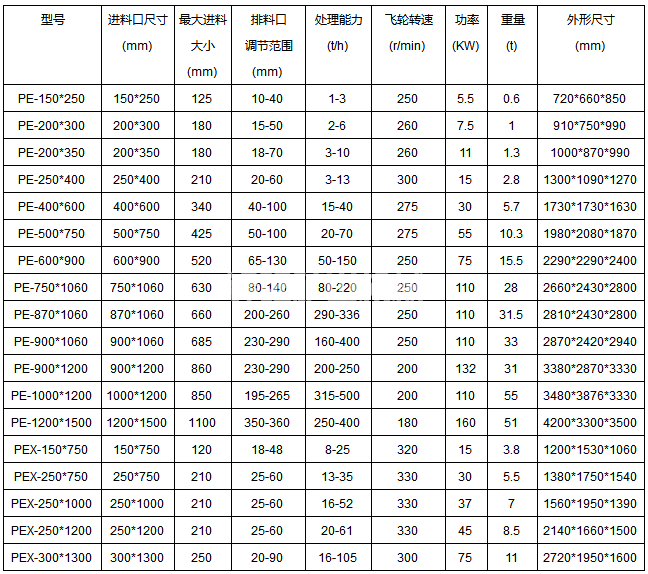

The Ebo crusher is used as a key coarse crusher and vertical crusher in mining, decorative building materials, basic construction and other units. According to the overall width of the feeding port, it can be divided into three types: large, medium, and small. Equipment with a total width of more than 600MM is classified as large and medium-sized equipment, while equipment with a total width of 300-600MM is classified as medium-sized equipment, and servers with a total width of less than 300MM are classified as small servers. The Ebo machine has a simple structure and is very easy to produce, making it reliable in work.

5、 Classification

The jaw crusher can be divided into simple swinging large jaw crushers (simple swinging jaw crushers) according to the different shaking methods of the themed movable jaw plates. There are three types of complex shaking large jaw crusher (compound swinging jaw crusher) and comprehensive shaking jaw crusher.

6、 Structural composition

One part of the work of jaw crusher equipment is two jaw plates. One is to fix the fixed jaw plate (fixed jaw), which is vertical (or slightly Camber angle above) and fixed on the front inner wall of the human body. The other is the theme movable jaw plate (moving jaw), which is slanted, and generates small crushing cavities (working cavities) in the upper, middle and lower parts with the fixed fixed jaw plate. The theme activity jaw plate moves regularly and repeatedly towards the fixed fixed jaw plate, sometimes separating and sometimes approaching. During separation, raw materials enter the crushing chamber and finished products are unloaded from below; When approaching, the raw materials installed between the two jaw plates are subjected to extrusion, bending, and fracture, resulting in crushing.

Free design solution

Free design solution

24-hour engineer dispatch

24-hour engineer dispatch

In order to better serve you, we can leave your needs here, such as handling materials, production capacity, and finished product requirements. A professional product manager will reply to you!

Copyright: Jinqiang Mining Machinery

quotes and solutions

+8619870423316