quotes and solutions

+8619870423316

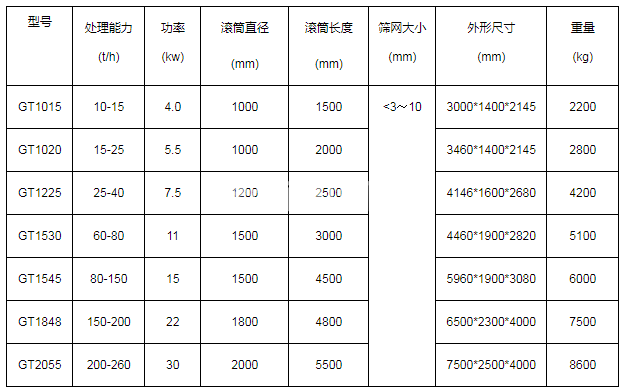

productivity:20-260t/d

Processing materials:Suitable for grading powdery materials, with excellent screening effect, using a 60-200 mesh sieve.

Application scope:0-143mm

Feed particle size:0-143mm

Equipment processing capacity:20-260t/d

Production materials:Suitable for grading powdery materials, with excellent screening effect, using a 60-200 mesh sieve.

1、 Introduction

The drum stone screening machine is a specialized screening machine and equipment developed for power plants, coking, decorative building materials, metallurgical industry, concrete, chemical plants, mining and other fields. The drum stone screening machine overcomes the problem of stainless steel mesh blockage caused by circular and linear vibrating screens when screening wet raw materials, and improves the production volume and stability of screening system software.

2、 Application field

Suitable for screening various raw materials with various characteristics, such as coal, coke, lime, etc., which are prone to clogging due to moisture and cold conditions. The size of the products under screening is 100mm, with a diameter of 10-50mm in the middle, and the fineness can reach below 3mm.

3、 Working principle

Large drum stone screener is divided into five parts: hexagonal drum, sound card rack, Büchner funnel funnel, reducer and motor. Various installation design schemes must be carried out according to specific production and manufacturing. After the crushed sand and gravel are fed into the drum, the raw materials are screened by the Centripetal force of the drum rotation and the jigging effect. Screen one by one using stainless steel screens with different mesh sizes. Sand and gravel with different specifications and models are screened and then dropped into the belt conveyor through Büchner funnel and sent to the finished stone yard. On the one hand, it is selected with the rotation of the drum, and raw materials are screened by the Centripetal force of the drum rotation and the jigging effect. On the one hand, the sand and gravel with large particle size distribution flow forward along the inclination of the drum, and are slowly screened according to the stainless steel screen with different meshes. Small sand and gravel materials fall into the respective Büchner funnel after screening, and then are transported manually or automatically out to the finished product stack.

4、 Advantage characteristics

1. Wide adaptability of raw materials: The drum type stone screening machine is widely used for screening various raw materials, whether it is fake or inferior coal, coal powder, or carbon smoke and other types of raw materials, all of which are smoothly screened.

2. The feeding methods are simple and diverse: the feeding port of the drum type stone screen developed by our company can be based on the specific design scheme on the spot, whether it is the drive belt, Büchner funnel or other feeding methods, without the need to adopt unique countermeasures,

All can smoothly feed

3. High screening efficiency: The machine equipment can be equipped with a comb shaped cleaning organization, which can screen the entire screening process regardless of how dirty or miscellaneous the raw materials enter the screening cylinder, thereby improving the screening efficiency of the machine equipment.

4. Large sieve weight, convenient for Import substitution industrialization: under the same specification, the circle area is larger than the total area of other shapes, so the reasonable total screening area is larger, so that raw materials can fully touch the stainless steel screen, so the sieve weight is larger per unit time. With its simple structure, convenient layout, novelty and perfect technology, it is very easy to be replaced by Import substitution industrialization.

5. The drum type stone screening machine motor developed by our company, which consumes less energy, has a low rated power, solving the problem that the power consumption of the same amount of raw materials in the same time is half to one-third of that of other screening types.

5、 Construction Description

1. Divided by size: large, medium, and small goods with a management center shaft and large, medium, and small goods without a management center spindle bearing. Large, medium, and small sizes are equipped with cross chair back transmission systems for electric motors and reducers; large and medium-sized sizes are equipped with transmission gear transmission systems.

2. The screen body is of a replaceable structure, which means that when the screen body is worn out and cannot be applied, it can be disassembled as a whole. There are standard accessories in the factory.

3. The screen body and screen bars are made of metal composite materials, and customers can repair and replace them independently. 4. The raw materials shall be transferred by belt conveyor immediately after being classified.

Free design solution

Free design solution

24-hour engineer dispatch

24-hour engineer dispatch

In order to better serve you, we can leave your needs here, such as handling materials, production capacity, and finished product requirements. A professional product manager will reply to you!

Copyright: Jinqiang Mining Machinery

quotes and solutions

+8619870423316